- Home

- About us

- Products

- Faqs

- Ammonia Industry Knowledge

- Syamcat Service FAQ

- Hydrodesulfurization Catalyst

- ZnO Desulfurizaiton Catalyst

- Pre Reforming Catalyst

- Primary Reforming Catalyst

- Secondary Reforming Catalyst

- High Temperature Shift Catalyst

- Low Temperature Shift Catalyst

- Methanation Catalyst

- Ammonia Synthesis Catalyst

- Methanol Synethesis Catalyst

- PSA

- CO2 Dehydrogenation Catalyst

- Formaldehyde Catalyst

- News

- Certificate

- Contact us

Innovative Design and Optimization of Cobalt-Based Catalysts for Enhanced Ammonia Synthesis

time2023/11/30

- SYAMCAT has strategically focused on the design and optimization of active components, particularly delving into the in-depth exploration of cobalt-based active metals.

Innovative Design and Optimization of Cobalt-Based Catalysts for Enhanced Ammonia Synthesis

In our pursuit of advancing ammonia synthesis catalysts, SYAMCAT has strategically focused on the design and optimization of active components, particularly delving into the in-depth exploration of cobalt-based active metals. This research aims to achieve higher scientific achievements in the catalysis field.

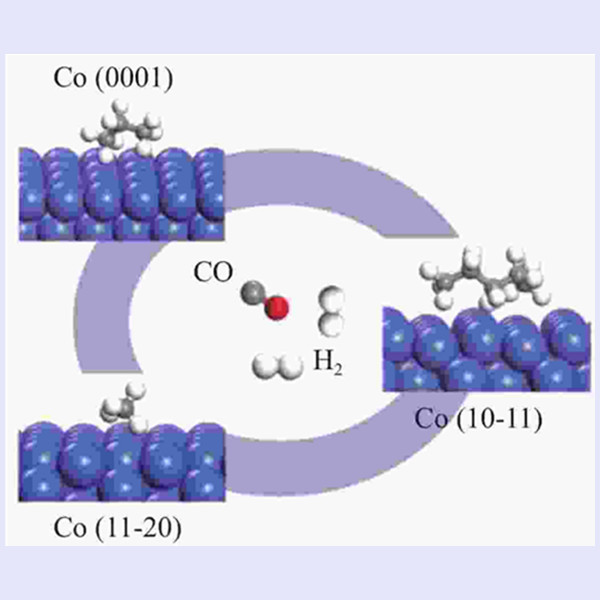

Microscopic Design of Active Metal

To enhance catalytic efficiency, we conducted extensive research on the catalytic performance of various metal active components. By wisely selecting cobalt as the primary active metal, we analyzed its electronic structure and reaction activity, confirming its outstanding performance in the synthesis of ammonia.

Microstructure Control and Application of X-ray Photoelectron Spectroscopy (XPS) Technology

Utilizing advanced surface analysis techniques like XPS, we delved into the microscopic interactions between active metals and carriers. Precise structural control optimized the distribution of active metals on the catalyst's surface, providing a profound scientific basis for the design of cobalt-based ammonia catalysts.

Correlation Study of Electronic Structure and Reductivity of Active Metals

Further research into the electronic structure of active metals focused on the relationship between their reduction states and catalytic performance. Monitoring electronic structure changes under ammonia reaction conditions deepened our understanding of the impact of active metal reduction on catalyst activity, offering theoretical support for precise control.

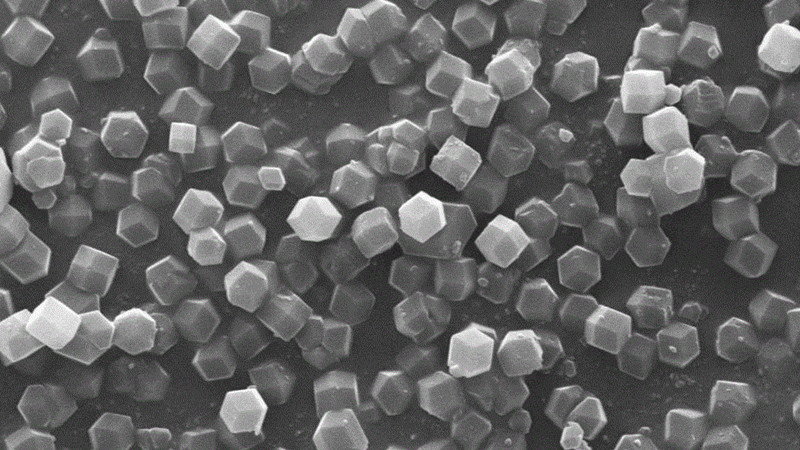

Optimization of Ratio and Microscopic Interaction Analysis

Microscopic-level optimization of the ratio between active metals and carriers was achieved to control their interaction. Through experimental design and computational chemistry, we achieved precise control of the cobalt-to-carrier ratio, enhancing the catalyst's selectivity and stability.

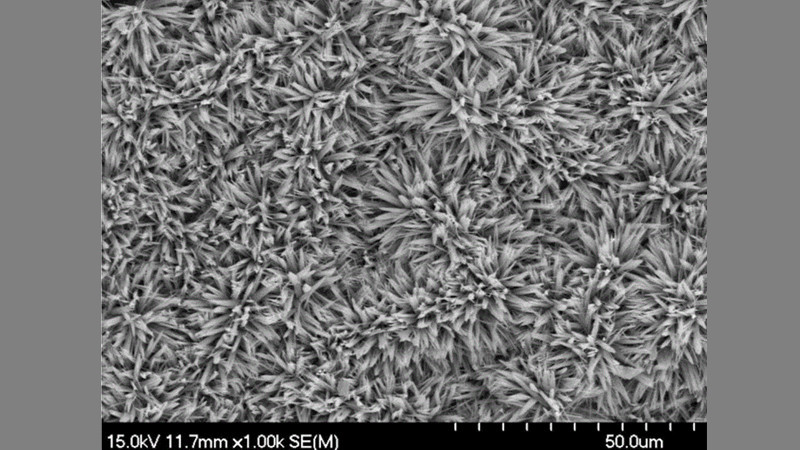

Surface Modification and Synergistic Effects of Additives

The introduction of surface modification techniques and specific additives, combined with their synergistic interaction with active metals, optimized the catalyst's surface properties. This microscopic surface modification contributed to improved resistance to poisoning and coking, enhancing stability in complex industrial environments.

Cobalt catalysts demonstrate efficient ammonia production at low temperatures, showcasing superior resistance to poisons without requiring high-temperature desorption. With better selectivity and activity at lower temperatures and pressures, cobalt ammonia catalysts are ideal for industrial applications.

Through these groundbreaking research innovations, SYAMCAT has successfully overcome traditional catalyst design limitations, introducing new perspectives and possibilities in the field of catalysis for ammonia synthesis. This in-depth research series will provide more efficient and sustainable catalyst solutions for industrial ammonia production. We remain committed to deepening our research, contributing our expertise, and fostering innovation for the future development of catalytic technologies.

The above briefly introduces “Innovative Design and Optimization of Cobalt-Based Catalysts for Enhanced Ammonia Synthesis” , If you would like to learn more or are in search of a manufacturer for ammonia synthesis catalysts for your company, please feel free to contact us.

SYAMCAT is a professional manufacturer of ammonia synthesis catalysts with over 30 years of catalyst experience and history. Through continuous technological innovation, we offer catalyst solutions for ammonia production. We are dedicated to assisting ammonia plants and fertilizer manufacturers in optimizing production efficiency while reducing environmental impact. Our aim is to contribute to the sustainability of global agriculture and food security.