- Home

- About us

- Products

- Faqs

- Ammonia Industry Knowledge

- Syamcat Service FAQ

- Hydrodesulfurization Catalyst

- ZnO Desulfurizaiton Catalyst

- Pre Reforming Catalyst

- Primary Reforming Catalyst

- Secondary Reforming Catalyst

- High Temperature Shift Catalyst

- Low Temperature Shift Catalyst

- Methanation Catalyst

- Ammonia Synthesis Catalyst

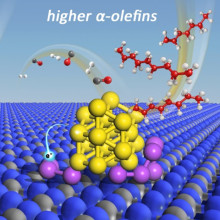

- Methanol Synethesis Catalyst

- PSA

- CO2 Dehydrogenation Catalyst

- Formaldehyde Catalyst

- News

- Certificate

- Contact us

-

Ammonia production is a crucial component of the global chemical industry, but it's often associated with high energy consumption and environmental impact.

time2023/09/01

-

In the realm of ammonia production, choosing the right catalyst supplier is paramount.

time2023/10/12

-

During the usage of the ammonia synthesis catalysts, there might be instances of temporary or long-term shutdowns.

time2023/10/26

-

It is a catalyst with dual active components, iron, and cobalt. During the melting process, cobalt oxide reacts with magnetite, forming a eutectic mixture.

time2023/11/02

-

SYAMCAT, a distinguished leader in the field of ammonia synthesis catalysts, has made significant strides in reducing production costs for ammonia plants.

time2023/11/08

-

SYAMCAT's ammonia synthesis catalysts exhibit high catalytic features at low temperatures, excellent heat and poison resistance, and easy restoration characteristics.

time2023/11/15

-

Once the production process for synthesizing ammonia and the internal components of the synthesis tower are determined, choosing the right catalyst becomes paramount.

time2023/11/23

-

In the critical realm of synthetic ammonia production, ammonia synthesis catalysts stand out as a decisive factor.

time2023/11/24

-

In our unwavering commitment to meet the growing demand for efficient ammonia synthesis, SYAMCAT employs cutting-edge R&D technologies to extend the service life of ammonia synthesis catalysts.

time2023/11/30

-

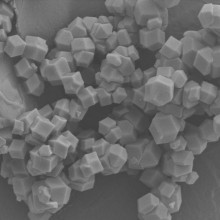

The intricate relationship between the reduction process and mass of reduction with the particle size of the catalyst is evident.

time2023/12/05

-

In the development of iron-based ammonia synthesis catalysts, our research team has achieved remarkable breakthroughs in catalyst additives.

time2023/12/07

-

Optimizing Catalyst Loading for Ammonia Synthesis: A Comprehensive Guide for Distributors and Agents

We are delighted to present a specialized guide tailored for ammonia synthesis catalyst distributors and agents.

time2023/12/12

-

In the field of ammonia synthesis catalysts, SYAMCAT's groundbreaking innovations in raw materials present a significant boon for distributors and agents.

time2023/12/15

-

Understanding the complexities of ammonia synthesis catalyst reduction is vital for achieving optimal results.

time2023/12/20

-

In a significant development for the synthetic ammonia industry, SYAMCAT, a leading ammonia catalyst supplier, has unveiled its latest innovation: the SYAMCAT A217/A217R catalysts.

time2023/12/22

-

Ammonia catalysts play a pivotal role in various industrial processes, particularly in ammonia plants, fertilizer factories, and engineering projects.

time2023/12/26

-

These ammonia catalysts not only enhance ammonia production efficiency but also contribute significantly to sustainability.

time2023/12/28

-

The reduction process and adjustments for ammonia synthesis catalysts encompass multiple steps to ensure both safety and efficiency in operation.

time2024/01/03

-

Our groundbreaking work on the SYAMCAT A217 ammonia catalyst not only raises the bar in reductive performance but also opens up new possibilities for optimizing your ammonia production.

time2024/01/05

-

These transformative measures promise enhanced production capabilities, extended service life of ammonia catalysts, and streamlined operations.

time2024/01/08

-

Our guide reveals how proper maintenance ensures peak performance, efficiency, and longevity, empowering your ammonia production.

time2024/01/09

-

Our dedicated teams are poised to provide you with professional and tailored answers, offering specialized solutions that align with your specific requirements.

time2024/01/16

-

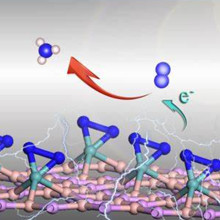

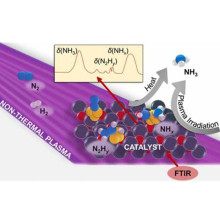

One effective method is the development of efficient, environmentally friendly ammonia catalysts, facilitating the rapid realization of green ammonia synthesis.

time2024/01/18

-

In the dynamic landscape of industrial processes, the pursuit of optimal ammonia synthesis takes center stage.

time2024/01/23

-

For those intrigued by revolutionizing ammonia synthesis, SYAMCAT is not just a catalyst but a pathway to the future.

time2024/01/26

-

The catalyst procurement department in ammonia synthesis plants plays a critical role in ensuring the facility's operational smoothness and efficiency.

time2024/01/30

-

In the dynamic field of ammonia synthesis, SYAMCAT is a catalyst for innovation and sustainability.

time2024/02/01

-

This exploration unveils the unique attributes of SYAMCAT catalysts, showcasing their potential to significantly enhance efficiency in the intricate process of steam reforming.

time2024/02/06

-

Embark on a revolutionary catalyst experience with SYAMCAT – your partner where efficiency seamlessly meets excellence.

time2024/02/09

-

With a focus on enhancing stability and performance, SYAMCAT steam reforming catalysts redefine the landscape of steam reforming catalysts, providing customers with reliable and stable production support.

time2024/02/16

-

It's also worth highlighting the efficacy of SYAMCAT steam reforming catalyst in mitigating catalyst deactivation and enhancing process efficiency.

time2024/02/23

-

SYAMCAT steam reforming catalyst plays a crucial role in optimizing the efficiency and performance of the reforming process.

time2024/02/21

-

Among them, steam methane reforming (SMR) in natural gas hydrogen production is the most established hydrogen production technology globally, constituting roughly 70% of global hydrogen production.

time2024/02/28

-

For expert guidance on mitigating chlorine-induced catalyst poisoning and optimizing hydrogen production processes, rely on SYAMCAT's seasoned team of catalyst specialists.

time2024/03/07

-

In methane steam reforming reactions, catalyst deactivation primarily occurs due to three factors: poisoning deactivation, coking deactivation, and sintering deactivation.

time2024/03/12

-

The generation of high-temperature water vapor or hydrogen prompts the conversion of most sulfur compounds to H2S, which subsequently adsorbs onto active sites, resulting in catalyst poisoning.

time2024/03/20

-

For steam reforming, noble metal catalysts show high activity due to strong methane activation and hydrogen evolution abilities, but their high cost hinders industrial-scale use. Among non-noble metal catalysts, Ni, Co, and Fe are key components, ranked in activity as Ni > Co > Fe. Nickel-based catalysts, with their comparable activity to noble metals and much lower cost, are especially promising for industrial applications.

time2024/06/06

PublisherLawrence

-

Avant's SYAMCAT Z428Q/SYAMCAT Z429Q catalyst series transforms industrial gas production with superior flow performance and minimal pressure drop. By integrating CO2 adsorption, it enhances hydrogen purity and lowers energy use. With advanced Ni-based catalysts and efficient adsorbents like CaO and lithium salts, it sets new eco-friendly standards, reducing emissions and improving efficiency markedly.

time2024/07/05

Publisherhoey

-

Avant Company revolutionizes industrial gas production with its SYAMCAT Z428Q/Z429Q catalysts. These catalysts feature self-regenerating technology, simplifying operations, shortening startup times, and improving efficiency. Their high reducibility ensures rapid reaction initiation and stable production while reducing energy consumption and emissions. Recognized for innovation and reliability, SYAMCAT catalysts provide efficient, eco-friendly solutions for industrial gas production.

time2024/07/08

Publisherhoey

-

Syamcat Z317/Z318 steam reforming catalysts play a critical role in refinery hydrogen production units. In April 2024, Syamcat provided on-site technical services for catalyst loading in a 20,000 Nm³/h hydrogen unit, ensuring optimal performance and receiving high praise from the end user for their professional service.

time2024/08/22

Publisherhoey